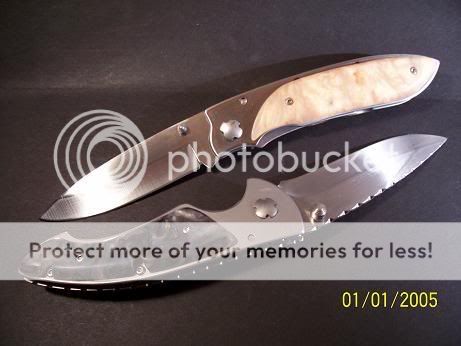

another....liner lock 8" overall. acrylic handle and backspine, fileworked blade and clip. made for a woman, thats why it looks a little girly.

ive tried to think of ways to resolve this issue for liner locks......liner locks and frame locks need screws as opposed to pins like used in lock backs and slipjoints. the only solution i have thought of for screws is only using epoxy to hold down the handles. while i trust 2 ton epoxy, i dont trust it that much so for now it will have to work.Vilham wrote:

looks good, shame about the screws being visible.

Don't blame the instrument, blame the user.Ty wrote:

Hardly appropriate talking about knives today after what happened to Knightnifer's friend.

http://forums.bf2s.com/viewtopic.php?id=63016

Just saying...

I intend to buy too.SEREMAKER wrote:

Hey Parker : I pmed you a while back bc I definitely want to buy 1 of your knives and you said you were slammed bc of x-mas, well just wondering if you can squeeze me in for 1 of your knives - love to have 1

a symbol somewhere on the ivory would be baller. maybe some sort of S because of the s spineT4rd wrote:

Looks pretty damn sweet! I think it would look better if it had some bad-ass tribal symbol on it somewhere, like on the blade. I like that kinda stuff (cept for tattoos).

You do some nice work. Am I crazy or does that blade face out when closed? I was thinking that I'd have to hold the inside of the curve in my palm to open and that wouldn't be comfortable.Parker wrote:

ok so i just finished a new knife for a customer, and since i get everyones opinion on everything else around here, can you guys tell me what you think?

it is an automatic, with a button action. pearl acrylic handles, 8 inches overall length, just shy of four inches of blade. very, very sharp edge, with filework on the bladespine. any comments welcome, thanks for looking.