cowami wrote:

Is the Damascus patterning hard to form? I remember reading an article about it.

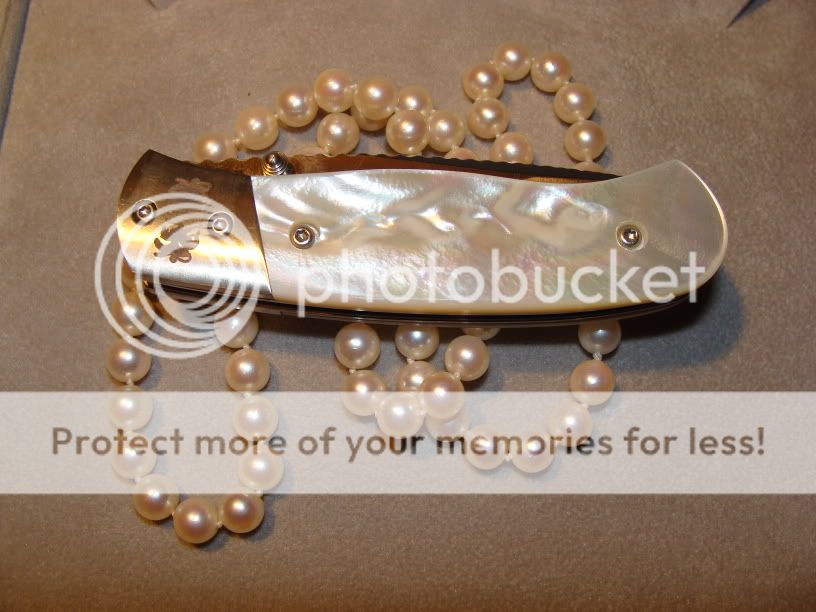

Looks , my STL buddy.

it all depends on what type of pattern.

that checkerboard pattern is a HUGE pain in the ass, and therefore, i charge accordingly.

however, most patterns are not so intricate.

start with two pieces of metal....say, .025 thick....one 1095 carbon steel, the other 15N20.

ok, so the first thing is to get them up to temp....let them hang out in a forge until they are at welding temp.

once they get there, take them out, put borax on (reducing carbon), and hammer them until they weld.....this needs to be done VERY quickly as the steel cools rapidly once its out of the forge.

as you hammer, you can decide what pattern you want to do....twist is just how it sounds....you take that billet that you welded together, put tongs on both ends, and CAREFULLY twist that motherfucker as much as you can.

grind to shape, etch....and bingo bango, you got yourself damascus.

it is kind of a pain in the ass, so i try to pick one day, and get as much done as i can.